PRODUCTS

EPP Molded Foam Packaging Services

The Benefits of EPP Molded

Foam Packaging

What is EPP Molded Foam Packaging?

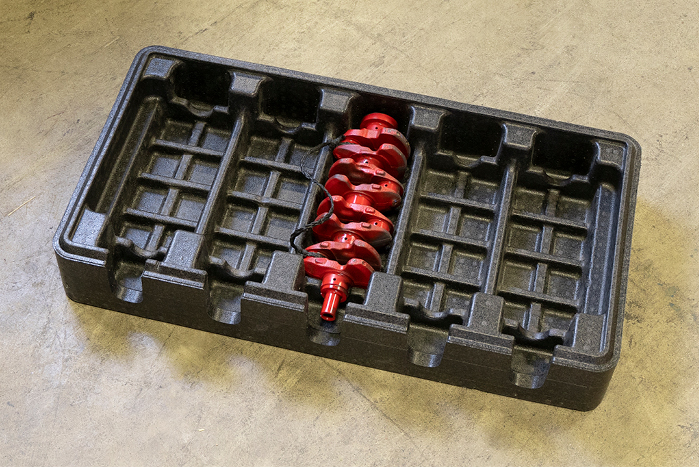

EPP molded foam is a lightweight, durable foam that can be precisely shaped to fit products and provide exceptional protection. EPP foam starts as small foam beads that are then expanded using heat and pressure inside a mold to form a solid foam structure. The result is packaging that conforms exactly to the contours of a product.

EPP molded foam can be created as packaging inserts, trays, end caps, and liners that fit snugly around products. It can also be used to create entire foam boxes or cases. Custom shapes and designs are easily created to specifically fit unique products.

The Benefits of Using EPP Molded Foam

Excellent Shock Absorption

The foam structure of EPP gives it outstanding ability to absorb impacts and cushion products from drops, shocks, and vibrations. The custom molded shapes fit tightly around products to keep them immobilized and protected.

Lightweight

EPP foam is lighter than expanded polystyrene foam. The lightweight nature reduces shipping costs, makes handling easier, and boosts sustainability.

Conforms to Odd Shapes

The molding process allows EPP foam to take on nearly any shape or contour needed to precisely fit a product. Odd shaped products or components can be securely cradled by the custom molded foam cavity.

Class A Finish

EPP has a smooth, consistent cell structure that won’t scratch or scuff sensitive product surfaces. Electronics, optics, and medical equipment with delicate coatings or finishes are well protected by EPP’s Class A surface.

Cost-Effective

For mid to high volume production runs, custom EPP foam packaging is very affordable, especially compared to injection molded plastic solutions. The tooling and setup costs are spread over the entire production run.

Sustainable

EPP foam is recyclable and made using polypropylene plastic which has high reuse potential in many industries. EPP is produced without harmful CFCs or VOCs.

The Custom EPP Foam Packaging Process

Design and Engineering

Packaging engineers work with you to create designs tailored to your product’s size, shape, weight and protection requirements. Factors like target costs, shipping methods, sustainability goals, and end use are taken into account.

Prototyping

3D printed and CNC machined foam prototypes are created so you can evaluate the design’s effectiveness. Virtual CAD prototypes are also used.

Precision Foam Molding

We use state-of-the-art foam molding machines and tooling to create EPP foam packaging components matched exactly to your product’s contours.

Secondary Packaging Integration

The EPP foam components can be engineered to integrate with corrugated boxes, steel racks, plastic containers, etc.

Production

Our large manufacturing capabilities and inventory of EPP foam allow us to produce volumes from 10 to millions of pieces. We can seamlessly scale up as your program grows.

Contact us to learn more

about EPP packaging

An innovative, green packaging solution.